Breaking Down The Chimney Condition Report

The 21 inspection points of the form are discussed in detail

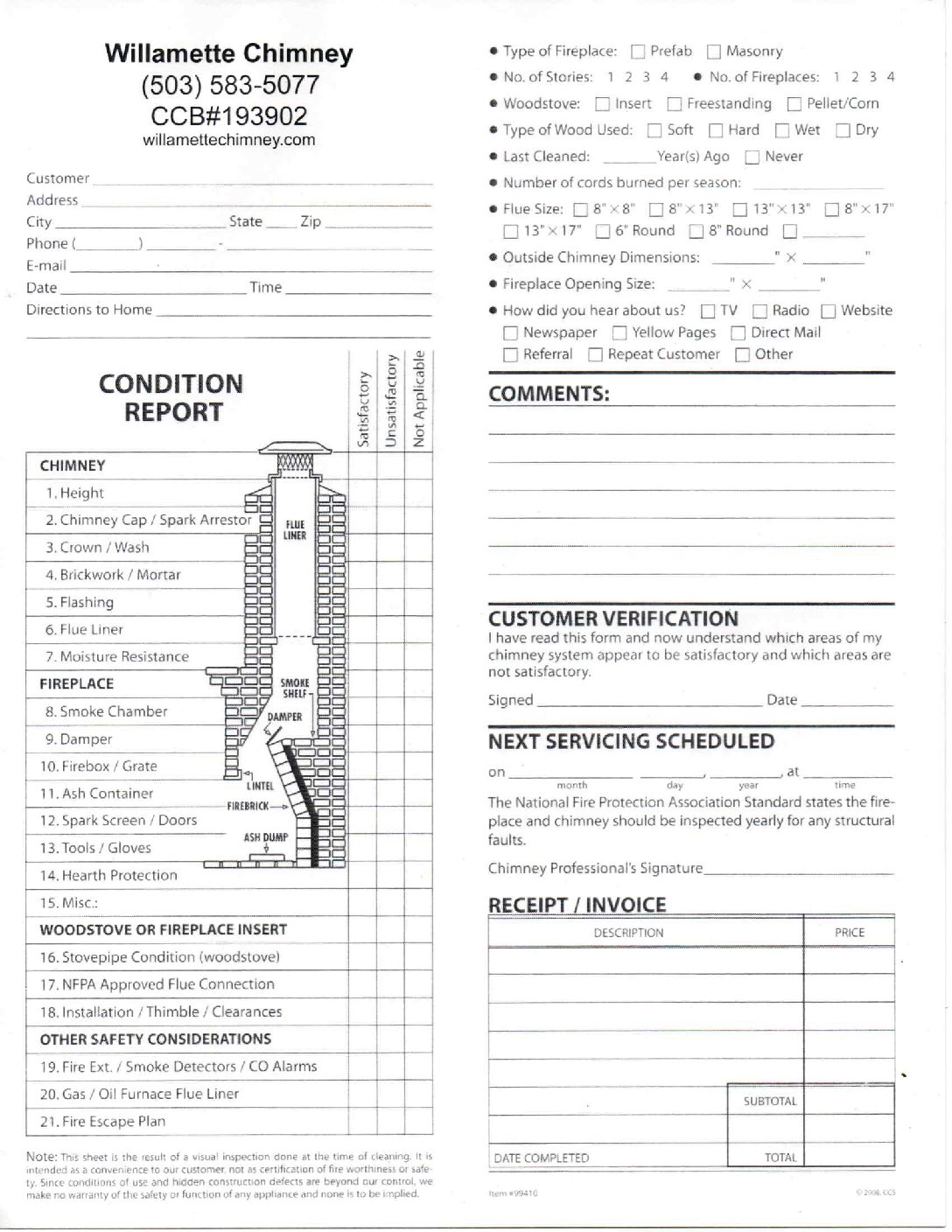

The Submitted Chimney Condition Report

The 21-point condition report is filled out and submitted with each cleaning and/or inspection we perform. Here is the breakdown of this report point by point:

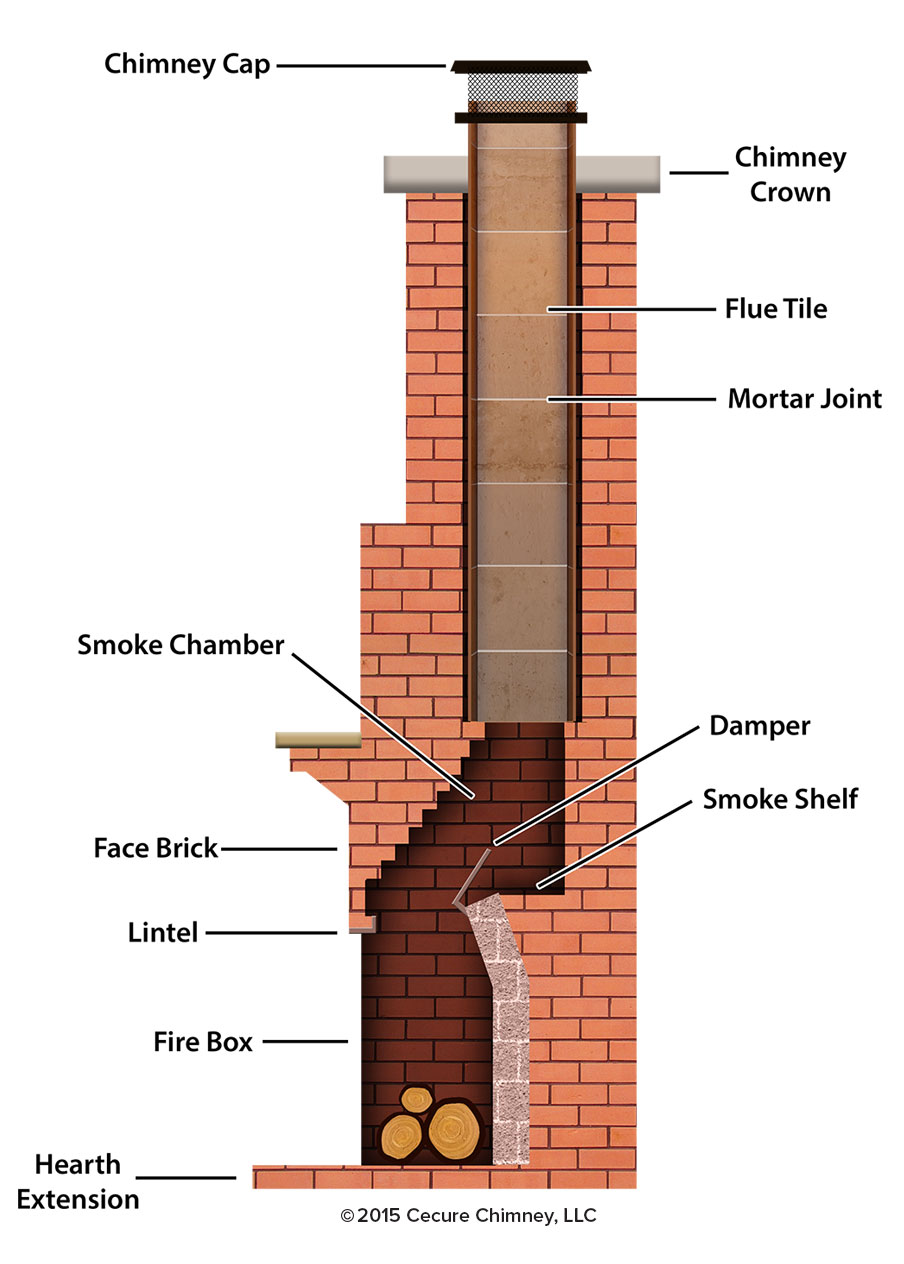

1. Height

Chimney height is critical to ensure proper draw of the fire smoke up and out of the chimney. There is a specific formula that is used as a baseline to determine how high to build a chimney, and in certain conditions the chimney needs to be built higher than the baseline determined by the height calculation formula.

2. Chimney Cap / Spark Arrestor

The chimney cap (rain cap) can keep rain and animals out of the chimney. It will not keep animals out if it does not have proper screening built into the cap. A rain cap will prevent costly repairs over time and keep animals out. Note: animals do crawl into chimneys and die, leaving a wonderful odor. It can be major chimney surgery to get them out (we have done it!) The chimney cap needs to be in good repair, of proper sizing, and firmly attached.

For extreme storm and down-draft conditions, check out the Monsoon Cap, made locally in Salem, Oregon, by Mongoose Metals. We purchase our Monsoon Caps and have all of our custom-made rain caps fabricated by our friends at Mongoose (Hi Paul!)

3. Crown / Wash

The crown seals off the top of the chimney and sheds rain and snow. Some chimneys may not have a crown due to their design not requiring one. Other chimneys are missing a crown and should have one installed. Crowns can crack in several places and still be bonded strongly to the brick. In this case, you want to seal the crown with Tamoseal to waterproof it and prevent it from further deterioration. If the condition of the crown serious, then a new crown should be poured on top of the chimney.

4. Brickwork / Mortar

At this point in the inspection, the bricks, blocks (CMUs or “concrete masonry units) or stone work is examined, as well as the condition of the mortar. a great preventative-maintenance action is to have your chimney waterproofed with siloxane. Brick and mortar can become saturated in heavy rains. When a wet chimney goes through multiple freeze-thaw cycles, the mortar can crack and erode. This is called “frost wedging.” The faces of brick and block can shed off, which is called “spalling.”

If the bricks are in good condition, but the mortar joints are looking worn, then tuckpointing the chimney (or a portion of it) may be the appropriate repair. If not, a rebuild of the chimney, or a portion thereof, may be in order.

5. Flashing

Chimney flashing is the pieces of metal at the bottom of the chimney, close to the roof. The flashing keeps water from running down the chimney into the house. Flashing that is missing or in bad repair can cause thousands of dollars of damage to the interior of the house (we have seen it happen.) Click here to learn what to look for.

6. Flue Liner

A chimney flue liner is an extra layer of protection within the chimney. There are many older chimneys that do not have a flue lining of any type. Flue liners can consist of hollow terra cotta sections stacked one upon another within the chimney. Chimneys without flue liners can be upgraded with flexible stainless steel liners. Take a deep dive here to learn all about it.

7. Moisture Resistance

If the chimney has no rain cap in place, then there is a moisture resistance problem, obviously. If the mortar joints are in bad shape (cracked up, missing, powdery) then you have moisture resistance issues. If your chimney is made of cinder blocks and the blocks are not painted or the paint job has failed, then you have moisture resistance issues. A worn, damaged or missing chimney crown can cause issues. Failed stucco work is another culprit.

8. Smoke Chamber

This chamber is larger than the actual vertical flue of the chimney that the smoke travels up. This space (the smoke chamber) is used to allow smoke to mix and curl in a circular motion and rise into the flue. The purpose of the smoke chamber is to compress the byproducts of combustion into a smaller space (the flue inside the chimney) without causing backdraft. This chamber can get very dirty with creosote deposits, and is cleaned from below using a long brush called a chamber brush. This chamber is usually (but not always) coated with mortar when the mason builds up the chimney. One of the reasons for coating this chamber is to smooth it out so that smoke can travel more easily up the chimney. The coating can wear away over time due to age, no rain cap on the chimney (rain thins the coating out over time,) and multiple chimney fires. Smoke chambers can be re-coated with high-temperature chamber coating mortars that are specific to our industry.

10. Firebox and Grate

The firebox is constructed of high-temperature fire brick and high-temperature refractory mortar. In rare instances you will see a firebox that has been constructed with regular brick and mortar, which is not a good idea because it will not stand up to the heat as well over time.

The fireplace grate is made of steel, and keeps the fire up off of the floor of the firebox. This helps the fire to burn better because air can flow underneath the fire, thus fueling the burn better. Grates come in small, medium and large sizes, and it is important that you have the correct size of grate in the firebox. A grate also helps to protect the floor of the firebox over time because it gets the burning wood up off of the floor.

9. Damper

The fireplace damper is to be closed when the fireplace is not being used, and any fires have stopped burning. If you were to close the damper of an open fireplace while a fire was burning or smoldering, the room would fill with smoke. The purpose of the fireplace damper when closed is to prevent heat loss up the chimney when the chimney is not in use. Woodstoves have adjustable dampers that regulate oxygen intake to the fire in the stove. A FIREPLACE DAMPER NEEDS TO BE OPEN ALL OF THE WAY WHEN USING THE FIREPLACE. IT IS NOT ADJUSTABLE LIKE A STOVE DAMPER, THAT IS, YOU EITHER HAVE IT ALL OF THE WAY OPEN, OR ALL OF THE WAY CLOSED. Dampers can rust to the point of non-function if there is no rain cap on the chimney for a long period of time.

Worn or missing dampers can be replaced by putting a top-of-chimney damper on top of the chimney:

(Looking up, typical fireplace damper at the top of the fireplace.)

11. Ash Container

Some open fireplaces have ash containers, and some do not. Some woodstoves have ash drawers that can be pulled out for easy disposal of ash. The fireplace will have a door at the back that ash can be scooted into. Somewhere on the exterior of the chimney will be a clean-out door to remove the ash. Older houses can have ash dumps that are quite large and take several years to fill up. It is best to clean out the ash dump annually. We do not clean out ash dumps as part of the chimney cleaning servlce. A worn or missing clean-out door needs to be replaced to prevent fire hazards. This is particularly true if the clean-out door is located inside the house (usually in the basement.)

12. Spark Screen / Doors

Spark screens keep sparks and embers from poppping out of the firebox and landing on carpets or wood floors. Glass doors do the same thing. When purchasing glass doors, read the literature and make sure that the glass is rated for high temperatures if you intend to close the doors while burning a fire. We sell and install Pleasant Hearth glass fireplace doors as we have found them to be well-constructed and economical. We do not recommend the accordian-type glass doors because it is difficult to clean the glass on the back side. We recommend the standard doors. They come with hinged spark screens.

13. Tools / Gloves

A high-quality, sturdy fireplace tool set is a must! Some of the tool sets sold are absolute junk. Stay away from sets that have handles (or anything else) that you have to screw onto the tool. Purchase fireplace tools that are single-pieced and relatively heavy in material. The stuff that screws together ALWAYS comes loose. Get a good pair of leather gardening gloves as well. The photo shows a good set of tools.

14. Hearth Protection

Generally, 16″ to 18″ of non-combustible material is called for in front of the fireplace opening. At the sides of the opening the hearth should extend at least 8″. Free-standing stoves on a raised hearth or on a floor need to have 18″ of non-combustible material all around the stove and under the stove. These specifications can vary according to the stove manufacturer’s installation specifications of the particular stove. It is possible that local building codes will override the manufacturer’s specifications. Usually this is not the case, but it can happen. Most areas require an installation to be permitted and inspected for final approval of the installation.

Item number 15 of the report is “Miscellaneous.” The technician uses this line item accordingly.

16. Stovepipe condition (woodstove)

Stovepipe is usually black, but sometimes is made of stainless steel, which will turn various colors over time due to heat. Some stove pipe is single-walled, and other is double-walled, meaning that there is a pipe within a pipe. Stove pipe can rust due to a missing rain cap and other types of water intrusion.

Over time, stovepipe can become worn and too thin for use; it can become damaged due to chimney fires.

17. NFPA Approved Flue Connection

The National Fire Protection Association (NFPA) is an international nonprofit organization devoted to eliminating death, injury, property and economic loss due to fire, electrical and related hazards. As of 2018, the NFPA claims to have 50,000 members and 9,000 volunteers working with the organization through its 250 technical committees.

There are various types of flue connections approved by the NFPA.

18. Installation / Thimble / Clearances

This point concerns the installation of the stove, the protective thimble that goes through a wall or penetrates a chimney (the stovepipe from the stove connects to the thimble), and clearances of pipes and stoves from combustible materials.

19. Fire Extinguisher / Smoke detectors / Carbon Monoxide Detectors

A strategically located fire extinguisher can save everyone concerned a lot of grief. It can save lives. It can save money – lots of it! You should have an appropriately -sized extinguisher on every level of the house. Inspect the gauge on them every 6 months to make sure they are still well-charged. The same applies to smoke detectors and carbon monoxide detectors. Make sure these detectors are installed in the appropriate places per the floor plan of your home.

20. Gas / Oil Furnace Flue Liner

This point has to do with a furnace that is vented into a chimney. Furnaces that are vented into chimneys can be fueled by natural gas, fuel oil and firewood. The chimney may have a traditional terra cotta or pumice liner (see point #6), it may have a liner inserted down the chimney that connects to the furnace exhaust pipe. An oil furnace would have a stainless steel liner installed to it, while a natural gas furnace would have an aluminum liner attached to it. There are many good reasons to have a liner installed to your furnace if it does not already have one installed. Click here to learn more about liners for your furnace.

21. Fire Escape Plan

If you are new to a home, you need to get yourself and others oriented to potential exits in the case of a fire that requires exiting the building. The best case scenario is that you can safely put out the fire with an extinguisher, etc. It is particularly critical to have a fire escape plan whith children. They need to be drilled on that plan regularly so that they can act automatically per the drill, when they are frightened. If there is more than one level of the house, they need to know how to deploy a fire escape ladder, and how to travel down it safely.